SMART MANUFACTURING

With the help of intelligent production lines, factories can remain competitive, reducing the time to market, production can be controlled more easily, while also greatly diminishing the risk of product recalls. Due to the need for large-scale data networks and data collection, the industry needs even more complex solutions, ones that need to be developed. In connection with this, the issue of data warehousing also arises, when the integrated storage of all data becomes an urgent necessity for the development and expansion of a company, it is recommended to implement the data warehousing as a solution.

As such, with the DIMHOB software developed by our engineers and developers, we do not offer a simple product, but rather a complete solution for process automation. With the introduction of the DIMHOB system, the entire production process is transparent, indirect processes can be automated, enabling faster and more flexible production. It can provide an excellent solution especially for medium-sized companies where there is no free internal capacity for large-scale automation projects.

Network, IoT and hardware components

Implementing wired and wireless networks. Ready to use settings for servers, computers, smart devices, sensors, cameras, etc.

Cloud technology and cyber security

Cloud-based IT brings many benefits to production companies, and our cyber security solutions help protect their data from potential damage.

Quick implementation of technologies

Our software solution can be well integrated with existing production technologies, MES systems, and new processes can be quickly integrated without major downtime.

Transparency in industry

OEE measurement (Overall Equipment Effectiveness), transaction tracking, real-time data collection, real-time inventory information.

Integration

Integration of multi-site processes, IoT devices, PLCs. A solution that can be adapted to existing ERP or MES systems.

Process transformation

Connecting and transforming processes: simplifying sessions and increasing efficiency on the production line.

PRODUCTION INFORMATION

DATA COLLECTION

Downtime, bug reports, run times, worker or shift performance

Data visualization

Data visualization, interactive user interfaces, actual and upcoming production or transition information

DATA WAREHOUSE

The big advantage of a data warehouse is the consolidation of large data from different sources.

74

projects

22

years of experience

16

dedicated colleagues

OTHER MODULES

DIMKEEP is a web-based software that enables users to set an expiration reminder for all important corporate documents. Reminders are sent with a specific due date, e.g., 2, 15, 30 days before the deadline. The option to add intervals is based on your own needs.

SCHEDULE EVERYTHING

Available data must be analyzed and the results displayed and appropriately used during the manufacturing process. Data gathered from different areas can provide information that can increase productivity and profitability.

PRODUCTION DATA VISUALIZATION

Collect, process, convert, sort, export, and compile data from various data sources – MsExcel, MsSQL, SqLite, MySql, MsAccess. Industrial devices – monitoring, controlling of production machines, sensors, scales, any device with Rs232-Ethernet-USB connection.

MERGE EVERYTHING

WHAT DO WE DO DIFFERENTLY?

In all cases, the goal of improvements is to bring innovation and create value with it. Our customers are looking for solutions to problems that are unprecedented, and their novelty content means their business value. Implementing innovations is inherently a risk.

All the measurable, collectable data generated during production and their interactions are cleaned and combined giving us a sample. From this sample, we get a solution key that gives us insight into the future. The data warehouse is also an excellent solution for increasing the quality, consistency, and accuracy of the data managed by the company, resulting in better decision-making for the management team.

WE CREATE THE BEST INDUSTRIAL PRACTICES

Digitization is absolutely necessary in all areas of manufacturing, creating not only opportunities for industrial data collection and data analysis, but also the communication of various IoT devices and industrial equipment throughout the factory.

Just as every industry has different characteristics, so does every production line. No two customer needs were the same and there are no best practices in many cases. We are therefore working on to develop these for our clients so that their production is efficient and traceable.

EXPERTISE

All the measurable, collectable data generated during production and their interactions are cleaned and combined giving us a sample. From this sample, we get a solution key that gives us insight into the future. In order to see this data and the information derived from it clearly, proper planning, coordinated IT and thoughtful development are required.

For most such assignments, we have to comply to an already existing production system and adapt an extremely large number of devices (camera, PLC, printer, RFID reader, etc.) to collecting data. SKYLINE's developers and engineers have gained a significant routine in the field of smart manufacturing over the years, so DIMHOB developments can be implemented during production without major downtime.

User-friendly, transparent interfaces,

designed according to customer expectations.

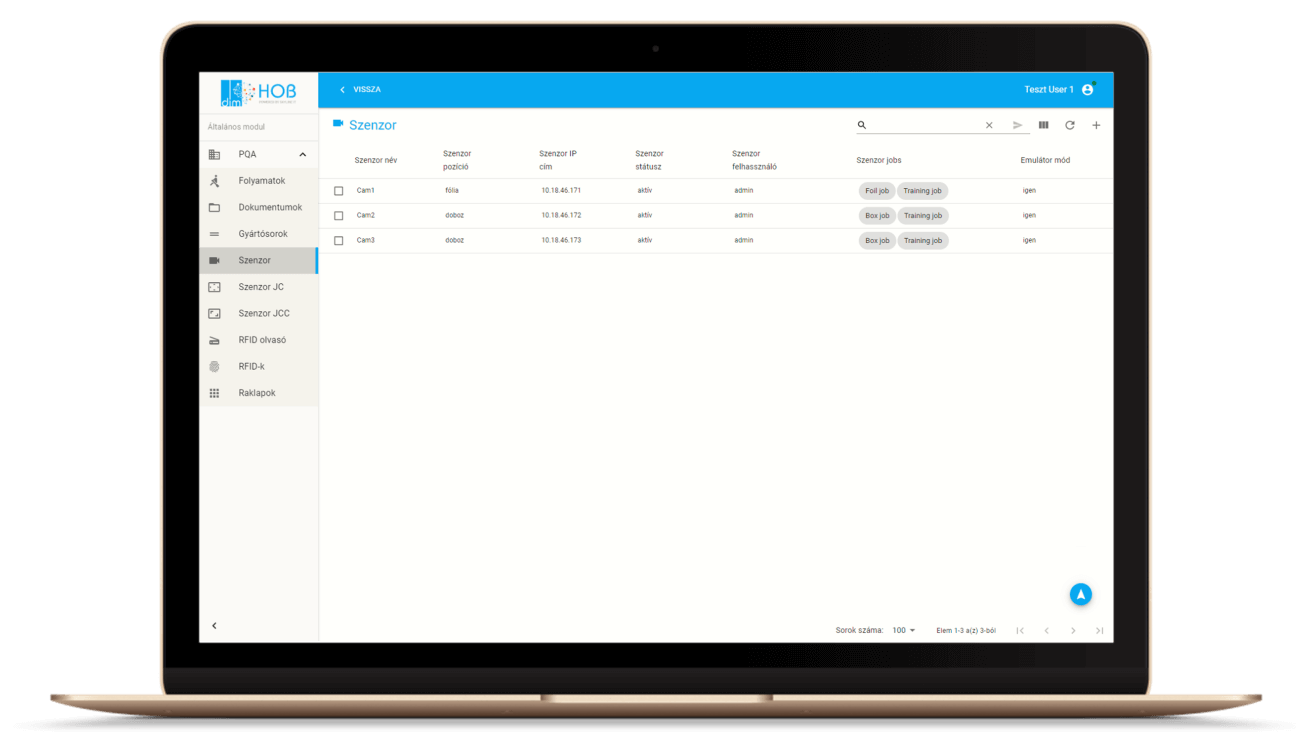

COGNEX SOLUTIONS

Tasks requiring industrial image processing are performed with COGNEX tools. As a market leader, COGNEX has a wide range of products to meet the different needs of the industry.

The field of application is extremely diverse. COGNEX image processing tools can reduce manufacturing errors, automate industrial operations, and provide fast and reliable quality control throughout the process.

DIMHOB connects the production control system to the cameras in an event-driven way, so you can remotely control exactly what you need to monitor on the assembly line or to transmit information from the cameras.

Cameras

Sensors

Code readers